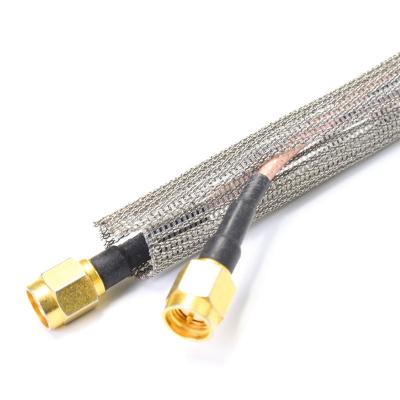

EMI Self-Closing Shielding Wrap

EMI self-closing shielding wrap crafted from high-density tinned copper wires woven with PPS (Polyphenylene Sulfide), this self-wrapping sleeve offers superior electromagnetic interference (EMI) and radio frequency interference (RFI) shielding. The overlapping wrap design ensures a secure fit and stable coverage (≥35%) around complex wire bundles, minimizing signal degradation and interference.

It's the ideal solution for engineers and OEMs seeking fast, tool-free installation, particularly in environments where cable disconnecting is impractical or costly.

With an operating temperature range from -40°C to +150°C, and resistance to heat, aging, humidity, and chemicals, it performs consistently in both harsh industrial and tropical climates—addressing key durability concerns for customers in Southeast Asia and Europe.

Features

High Shielding Performance

Compliant with GB/T30142-2013, ensures stable EMI/RFI protection across frequencies.

Quick & Non-Invasive Installation

Self-wrapping design allows easy application without disconnecting cables or connectors.

Flame Retardant

Meets EN45545-2 R22/23 HL3 fire safety standards—ideal for railway and transportation systems.

Wide Operating Temperature

Withstands -40°C to +150°C, suitable for extreme cold and hot, humid conditions.

Superior Ageing and Chemical Resistance

No deformation, burrs, or wire breakage after 20 hours at 100°C.

Withstands 110°C / 150 KPa in saturated humid steam for 48 hours.

RoHS & REACH Compliant

Fully compliant with international environmental safety standards.

Standard Color

Elegant and professional Silver finish for OEM visibility and branding.

Physical Properties

Material

Tinned Copper Wire & Nylon Multifilament

Working Temperature

-40℃ ~ +150℃

Flammability

Self-extinguishing

Shielding Effectiveness

≥75 dB (30 MHz - 3 GHz) per GB/T 30142-2013.

Standard Color

Tin-plated copper

Rohs Compliant

Yes

Reach Compliant

Yes

Cutting Tool

Scissor

Specification

Part No

Flat Width(W)

Expanded Range(mm)

Packing Length (m/spool)

Inch

mm

Min.(l)

Max.(O)

MBS-TC-003-TC

1/8"

3±1

1

4

250

MBS-TC-006-TC

1/4"

6±1

5

8

200

MBS-TC-008-TC

5/16"

8±2

6

12

200

MBS-TC-010-TC

3/8"

10±2

7

17

150

MBS-TC-012-TC

1/2"

12±2

8

20

100

MBS-TC-016-TC

5/8"

16±2

10

20

100

MBS-TC-020-TC

3/4"

20±2

13

26

50

MBS-TC-025-TC

1"

25±2

18

33

50

MBS-TC-032-TC

1-1/4"

32±2

20

50

50

MBS-TC-038-TC

1-1/2"

38±2

30

60

50

MBS-TC-045-TC

1-3/25"

45±2

35

75

25

MBS-TC-050-TC

2"

50±2

40

80

25

Why It Solves Regional Pain Points

Region

Key Concern

How E-FLEX® Helps

Europe

Strict fire safety & RoHS compliance

Certified to EN45545-2 & environmental regulations

Southeast Asia

High humidity, temperature swings, fast installation

Wide thermal range & tool-free wrap structure

Global OEMs

Signal integrity, fast retrofit needs

EMI shielding + connector-free installation

Application

Tinned copper shielding sleeve is trusted across a wide range of industries:

Automotive Wire Harnesses

EMI-safe design enhances onboard electronics reliability in EVs and hybrids.

Railway Systems

Compliant with EN45545-2 for fire safety, ideal for mass transit wiring.

Telecommunications

Protects signal integrity in high-frequency data transmission lines.

Industrial Automation & Control

Prevents signal disruption in sensor and control cable systems.

Defense & High-Performance Electronics

Robust shielding under mission-critical and high-vibration conditions.

English

English