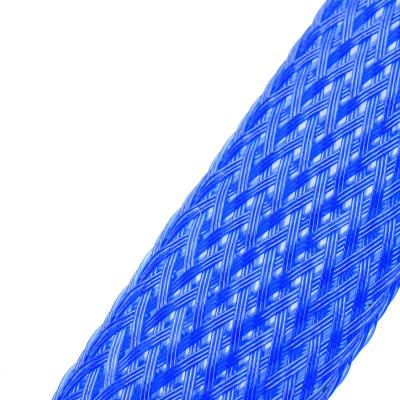

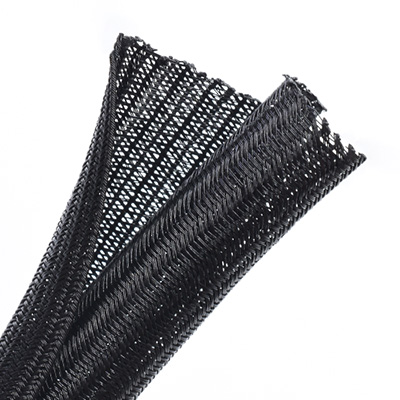

Automotive Self Wrapping Split Braided Wire Sleeving

Split braided wire sleeving made of 0.25mm or 0.38mm thick polyester filament.The lateral split design of the tube enables it to expand, accommodating a wide range of bundling needs. The semi-rigid braid effortlessly closes around the entire installation, eliminating the need for additional fasteners like Velcro® or tape.

The split braided wire sleeving are very flexible,high abrasion resistance,flame retardant,UV resistance,resist most of oils, common fuels and solvents. It keep high performance in wide operating temperature range.

Split braided wire sleeving can bend tightly without distorting or splitting, maintaining the flexibility of harnesses unlike fully rigid tubing. It also allows for easy addition or removal of wires without disassembly.

Certifications

Physical Properties

| Physical Properties | Details |

| Material | PET Monofilament + PET Multifilament |

| Working Temperature | -40°C ~ +150°C |

| Melt Point | 240(±10)°C |

| Low Temperature Resistance | No crack and degradation after test at -40℃ for 4h |

| Short - term aging | No crack and degradation after test at 158℃ for 168h |

| Flammability | VW - 1, FMVSS302 |

| Abrasion Resistance | Conform to grade 10(4000 cycles)refer to ISO6722 |

| Liquid Resistance | No cracking or degradation refer to GMW14327 |

| Ageing Resistance | Refer to ISO6722 |

| Overlap | ≧35% |

| UL File No | E533019 |

| Standard Color | Black |

| Certification | Rohs, Reach, UL, Halogen Free |

| Cutting Tool | Hot Knife |

What's Special about Split Braided Wire Sleeving?

1.Made of PET filament

2.Flammability: VW-1,FMVSS302

3.Extremely lightweight

4.Keeps it's flexibility under a wide range of temperatures

5.Easy, cost and labor effective installation

6.Resists gasoline, chemicals & cleaning Solvents

Specification

| Part No |

Nominal

Size

(mm)

|

Spread

Width

(mm)

|

As-Formed Dimension |

Bundle Dia

Range

(mm)

|

Packing

Length

(m/spool)

|

|

|

ID

(mm)

|

OD

(mm)

|

|||||

| SBW-PET-003-BK | Φ3.0 | 23±3 | 3±1 | 4±1 | 2~4 | 200 |

| SBW-PET-006-BK | Φ6.0 | 28±3 | 6±2 | 8±2 | 4~7 | 200 |

| SBW-PET-008-BK | Φ8.0 | 45±3 | 8±2 | 10±2 | 6~10 | 100 |

| SBW-PET-010-BK | Φ10.0 | 53±3 | 10±2 | 12±2 | 8~11 | 80 |

| SBW-PET-013-BK | Φ13.0 | 60±5 | 13±2 | 15±2 | 12~15 | 50 |

| SBW-PET-016-BK | Φ16.0 | 76±5 | 16±2 | 18±2 | 15~18 | 200 |

| SBW-PET-019-BK | Φ19.0 | 89±5 | 19±2 | 21±2 | 18~22 | 100 |

| SBW-PET-025-BK | Φ25.0 | 115±5 | 25±2 | 27±2 | 23~26 | 50 |

| SBW-PET-029-BK | Φ29.0 | 127±5 | 29±2 | 31±2 | 28~30 | 50 |

| SBW-PET-032-BK | Φ32.0 | 143±5 | 32±2 | 34±2 | 29~34 | 50 |

| SBW-PET-038-BK | Φ38.0 | 160±10 | 38±2 | 40±2 | 35-40 | 25 |

| SBW-PET-050-BK | Φ50.0 | 205±10 | 45±2 | 48±2 | 46~51 | 15 |

| SBW-PET-076-BK | Φ76.0 | 340±10 | 50±4 | 52±4 | 50~79 | 15 |

Application

MJ split braided wire sleeving widely use for industrial cable,A/V cable,Hdmi cable,wire harness,pneumatic hoses, hydraulic lines and highly polished or threaded machine parts, due to its open weave design with high abrasion resistance and high flame retardant.

English

English