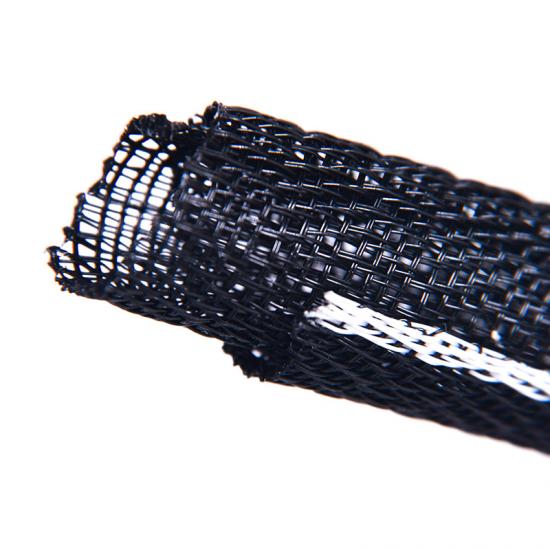

Automotive Split Braided Mesh Wire Loom

E-FLEX® Split Braided Mesh Wire Loom offers similar impact and crush resistance as premium V0-rated industrial braided sleeves.ade of polyester filament.The special braid construction permits the sleeving to be installed or removed easily.The lateral split allows the tube to open up to accommodate a wide variety of bundling requirements without the necessary of any secondary sealing technique,like cable tie, hook and loop, clip etc.

Automotive braided wire loom are very flexible,high abrasion resistance,flame retardant,UV resistance,resist most of oils, common fuels and solvents. It keep high performance in wide operating temperature range.

Physical Properties

Physical Properties

Details

Material

Polyester

Working Temperature

-40°C ~ +125°C

Melt Point

240(±10)°C

Flammability

Refer to DIN5510, accord with S - 4 SR - ST2 - 2 grade

Oxygen index

Refer to DIN EN ISO 4589 - 2, ≥37%

Low temperature resistance

Refer to - 20℃, after 100H test operation, there should be no visible change in appearance; Switching (or handling) operation, there should be no damage and broken.

Heat resistance

Refer to 80℃, after 2, 190H test operation, there should be no visual damage to appearance; After 150℃, 24H test operation, there should be no damage and broken.

Abrasion Resistance

Refer to GMW14327/(ISO722 - 1), ≥1482 times

Overlap

0.5

Standard Color

Black with White Identification Line

Cutting Tool

Hot Knife

What's Special about Split Braided Mesh Wire Loom?

1.Made of PET filament

2.Flammability: VW-1, DIN5510,EN45545

3.Extremely lightweight

4..Keeps it's flexibility under a wide range of temperatures

5.Easy, cost and labor effective installation

6.Resists gasoline, chemicals & cleaning Solvents

7.Cut & abrasion resistant

Specification

| Part No |

Nominal

Diameter

(mm)

|

Recommended Application

Range

|

Thickness

(mm)

|

Packing

Length

(m/spool)

|

|

| Min Φ | Max Φ | ||||

| STW-PES-005-BK | 5 | 1 | 5 | 0.7±0.15 | 100 |

| STW-PES-008-BK | 8 | 6 | 8 | 0.7±0.15 | 100 |

| STW-PES-013-BK | 13 | 9 | 13 | 0.7±0.15 | 100 |

| STW-PES-016-BK | 16 | 13 | 16 | 0.7±0.15 | 50 |

| STW-PES-019-BK | 19 | 14 | 19 | 0.7±0.15 | 50 |

| STW-PES-025-BK | 25 | 20 | 25 | 0.7±0.15 | 25 |

| STW-PES-029-BK | 29 | 26 | 29 | 0.7±0.15 | 25 |

| STW-PES-032-BK | 32 | 30 | 32 | 0.7±0.15 | 25 |

| STW-PES-038-BK | 38 | 33 | 38 | 0.7±0.15 | 25 |

| STW-PES-050-BK | 50 | 39 | 50 | 0.7±0.15 | 25 |

Application

Split braided mesh wire loom popular use in railway and automotive industrial where the wire harness and hoses need high flame retardant, heat dispersion and durable protection.

English

English