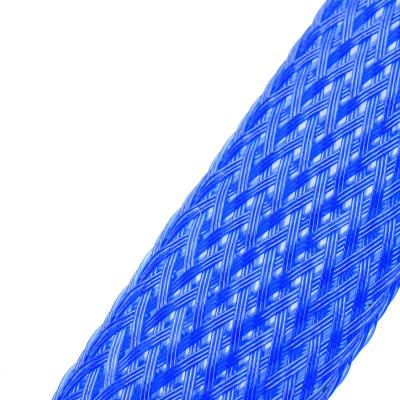

Self-Wrapping Anti-Abrasion Sleeving

Self-rolling design

No need for tape or cable ties to fix, the sleeve can automatically curl and wrap the wire harness, fit tightly and easily adjust, suitable for complex wiring environments.

Save installation time, especially suitable for batch operations or operations in small spaces.

Excellent anti-tear performance

The use of glass fiber and polyester fiber has excellent resistance to rodents (such as mice) and protects the cable from damage.

The surface texture can further increase the wear resistance, resist friction and scratches from sharp objects.

Environmental adaptability

Oil-resistant, acid-resistant, alkali-resistant, and UV-resistant, suitable for harsh environments such as industry, automobiles, ships, and outdoor equipment.

A wide operating temperature range (usually -40℃ to +150℃) meets the needs of different climatic conditions.

Flexibility and compatibility

A variety of diameter specifications are available to adapt to different thicknesses of wire harnesses or pipes.

Can be combined with other protective products (such as corrugated pipes and braided pipes) to form multi-layer protection.

Certifications

Physical Properties

Physical Properties

Details

Material

Fiberglass + Polyester

Working Temperature

-40°C ~ +150°C

Melt Point

240(±10)°C

Flammability

UL94 V2, FMVSS302

Overlap

≥35%

Standard Color

White/Black/Trace

ROHS Compliant

Yes

Reach Compliant

Yes

Halogen Free

Yes

Self Extinguishing

Yes

Cutting Tool

Scissor

Specification

Part No

Min

Max

STW-PGF-005-WH/BK-RR

5

29

0.65

4

6

200

STW-PGF-008-WH/BK-RR

8

46

0.65

6

9

100

STW-PGF-010-WH/BK-RR

10

50

0.65

8

11

80

STW-PGF-013-WH/BK-RR

13

65

0.65

12

14

50

STW-PGF-016-WH/BK-RR

16

75

0.65

15

17

100

STW-PGF-019-WH/BK-RR

19

97

0.65

17

20

100

STW-PGF-025-WH/BK-RR

25

125

0.65

23

26

50

STW-PGF-029-WH/BK-RR

29

145

0.65

27

31

50

STW-PGF-032-WH/BK-RR

32

164

0.65

29

34

50

STW-PGF-038-WH/BK-RR

38

184

0.65

37

40

50

STW-PGF-050-WH/BK-RR

50

245

0.65

48

52

25

Application

Automotive industry: Engine compartment wiring harness protection to prevent high temperature wear or animal chewing.

Industrial equipment: Factory machinery cable protection to reduce damage caused by vibration and friction.

Rail transit: Rodent-proof design for cables at the bottom of trains.

Energy field: Long-term protection of exposed cables in wind power and photovoltaic equipment.

English

English