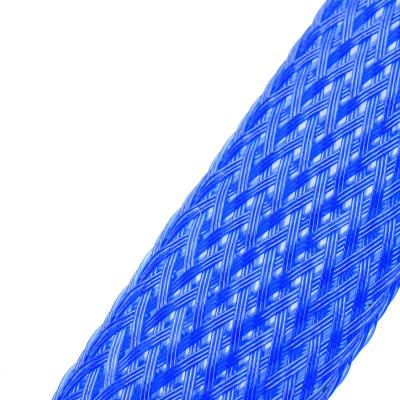

Highly Wear-Resistant Densely Woven Flame-Retardant Braided Sleeve

Using high-strength PET (polyester) material for weaving, it has strong wear resistance and can effectively prevent the cable from being damaged in a friction environment.

The dense weave structure enhances the surface scratch resistance and is suitable for use in dynamic bending and complex environments.

Compared with ordinary braided network tubes, the weaving is tighter, the pores are smaller, the coverage is stronger, and the protection is more comprehensive. It is suitable for scenes with higher requirements for appearance neatness and resistance to external forces.

The material has passed the UL94 V-0 or FMVSS302 flame retardant grade test, self-extinguishes when exposed to fire, delays the spread of flames, and improves safety of use.

Common flame retardants are halogen-free, environmentally friendly and safe, and comply with RoHS standards.

The operating temperature range is wide, generally -40℃ ~ +150℃, and special materials can reach more than +200℃.

While maintaining a soft feel, it has a certain degree of elasticity, which is easy to install and construct.

Certifications

Material

PET monofilament

Filament Dia

0.25mm(0.01”)

Working Temperature

-40℃~ +150℃

Melt Point

240+(-)10℃

Low temperature resistance

No signs of embrittlement or degradation after test at -40℃ for 4h

Heat aging resistance

No signs of embrittlement or degradation after test at 158℃ for 168h

Flammability

FMVSS302,UL94 V0

Abrasion Resistance

ISO19642-2:2023

Standard Color

Black,Orange

Certification

Rohs,Reach,Halogen Free

Cutting Tool

Hot Knife

Specification

Part No

Flat Width(W)

Expanded Range(mm)

Inch

mm

Min.(I)

Max.(O)

BRS-PET-006-BK-HD-FR-HA

1/4”

6

5

8

0.85±0.05

400

BRS-PET-008-BK-HD-FR-HA

5/ 16”

8

6

10

0.85±0.05

300

BRS-PET-009-BK-HD-FR-HA

9/25”

9

8

12

0.85±0.05

300

BRS-PET-010-BK-HD-FR-HA

3/8”

10

9

15

0.85±0.05

300

Application

Automotive wiring harness protection: engine compartment, underbody and other high-wear areas

Industrial automation equipment: cable chain, cable track internal protection

Railway transportation and military industry: cable management with high wear resistance and fire protection requirements

Robots and motion control systems: cable protection in frequently bent positions

Home theater/machine room organization: improve aesthetics and prevent cable wear

English

English