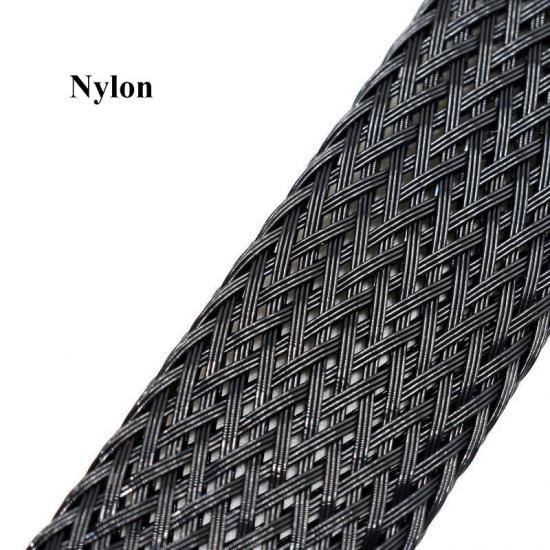

Flexible Nylon Electrical Braided Wire Sheathing

Nylon wire harness sheathing is braided from nylon 66 monofilament. The tight braid construction covers fully and provides excellent surface abrasion resistance for assemblies exposed to excessive wear. The smooth nylon fibers and tight construction also reduce abrasion damage caused by hoses and harnesses rubbing against the inside wall of the nylon hose sleeve.

Offering superior abrasion resistance, chemical tolerance, and long-term durability for industrial and automotive wiring protection.

With excellent flexibility and a wide operating temperature range from −40°C to +150°C, this sleeving is ideal for applications that require frequent cable movement, protection against mechanical wear, and extended service life in harsh environments.

Certifications & Compliance

Physical Properties

Physical Properties

Details

Material

Polyamide6-6 monofilament

Working Temperature

-40°C ~ +150°C

Melt Point

256(±10)°C

Low temperature resistance

No signs of embrittlement or degradation after test at -40°C for 4h per GMW14327

Heat aging resistance

No signs of embrittlement and degradation after test at 150°C for 504h per GMW14327

Flammability

Combustion rate <100mm/min per FMV SS302

Abrasion Resistance

Confirm to GMW14327 class 5(15000 - 29999 times)per ISO672-1

Standard Color

Black

Certification

Rohs

Halogen Free

Yes

UV Resistant

Yes

Cutting Tool

Hot Knife

What's Special about Nylon Electrical Braided Wire Sheathing?

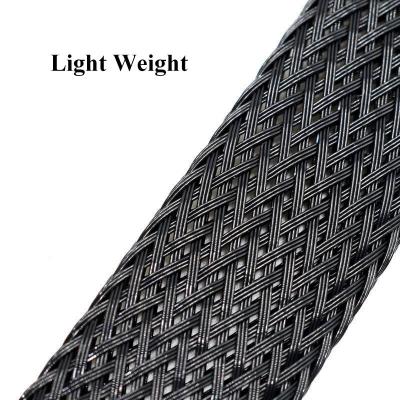

1.High Flexibility – Maintains performance under continuous bending and motion

2.Chemical Resistance – Resistant to oils, fuels, solvents, and common automotive fluids

3.Flame Behavior – FMVSS302 compliant, burning rate <100mm/min

4.Cut & abrasion resistant to protect hoses from excessive wear.

5.UV resistant for outdoor usage.

6.RoHS Compliant (UL 94 V2 or V0 optional upon request)

Specification

Part No

Flat Width(W)

Expanded Range(mm)

Inch

mm

Min.(I)

Max.(O)

BRS-PA66-003-BK

1/8”

3

1

6

1000

BRS-PA66-006-BK

1/4”

6

3

9

500

BRS-PA66-008-BK

5/16”

8

5

12

350

BRS-PA66-010-BK

3/8”

10

7

17

350

BRS-PA66-012-BK

1/2”

12

8

20

300

BRS-PA66-016-BK

5/8”

16

10

27

250

BRS-PA66-020-BK

3/4”

20

14

30

200

BRS-PA66-025-BK

1”

25

18

33

200

BRS-PA66-032-BK

1-1/4”

32

20

50

150

BRS-PA66-038-BK

1-1/2”

38

30

60

100

BRS-PA66-045-BK

1-3/4”

45

35

75

100

BRS-PA66-050-BK

2”

50

40

80

100

BRS-PA66-064-BK

2-1/2”

64

45

105

50

BRS-PA66-076-BK

3”

76

64

120

50

Why Choose Nylon Over PET?

| Property | Nylon Braided Sleeve | PET Braided Sleeve |

| Abrasion Resistance | ★★★★★ | ★★★★☆ |

| Melt Point | 256+(-)10°C | 240+(-)10°C |

| Flamemability | Combustionrate<100mm/minperFMVSS302 | FMVSS302 / VW-1 |

| Tensile Strength | High | Medium |

| Flexibility | Excellent | Good |

Application Scenarios

- Automotive wiring harnesses (engine bay, underbody, EV systems)

- Industrial machinery cables (robotic arms, conveyor systems)

- Marine and aerospace cabling

- Heavy-duty equipment wire bundles

- Server rooms, data centers, and telecom wiring

FAQ

1. Do you provide free samples?

• Special cases may be approved by management

• Black standard samples: 1–2 meters free, freight collected

• Colored / ODM samples: extra cost depending on supplier

................................................................................................................................................................................................................................................

2. What is your minimum order quantity (MOQ)?

• Black standard products: MOQ = one roll (first 3 orders allowed)

• Standard colors: usually 2000 meters (depends on yarn inventory)

................................................................................................................................................................................................................................................

3.What is your typical lead time?

Regular lead time: around 10 days

Urgent orders: about 5 days

................................................................................................................................................................................................................................................

4. Do your products have UL certification?

Yes. Our PET braided sleeving, self-closing braided wrap, textile wrap, self-closing conduit, and full-elastic wrap are UL-certified.

................................................................................................................................................................................................................................................

5. Do you have ISO and other quality system certifications?

Yes. We are certified with:

• ISO 9001

• ISO 14001

• ISO 13485 (medical)

• IATF 16949 (automotive)

................................................................................................................................................................................................................................................

6. Can you customize packaging?

Yes, based on required quantity and product type.

English

English