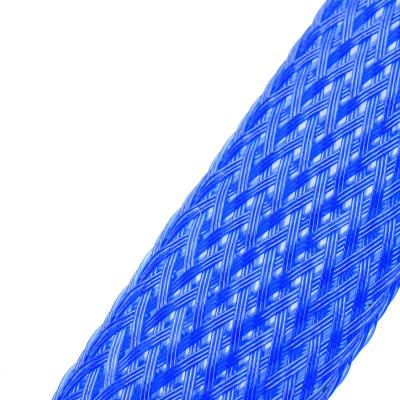

Split Flexible Semi-Rigid Pet Braided Sleeving Tube

Split flexible braided sleeving allows the tube to open up to accommodate a wide variety of bundling requirements, and the semi-rigid braid configuration simply closes around the entire installation without the need for any additional fasteners.

Certifications

Physical Properties

| Physical Properties | Details |

| Material | PET Monofilament + PET Multifilament |

| Working Temperature | -40°C ~ +150°C |

| Melt Point | 240(±10)°C |

| Low Temperature Resistance | No crack and degradation after test at -40℃ for 4h |

| Short - term aging | No crack and degradation after test at 158℃ for 168h |

| Flammability | VW - 1, FMVSS302 |

| Abrasion Resistance | Conform to grade 10(4000 cycles)refer to ISO6722 |

| Liquid Resistance | No cracking or degradation refer to GMW14327 |

| Ageing Resistance | Refer to ISO6722 |

| Overlap | ≧35% |

| UL File No | E533019 |

| Standard Color | Black/Red |

| Certification | Rohs, Reach, UL, Halogen Free |

| Cutting Tool | Hot Knife |

What's special about Split Flexible Pet Braided Sleeving Tube?

1.Easy, cost effective installation

2.More flexible than split convoluted or spiral wrap

3.Retains shape & rigidity

4.Easier to cover long lengths of wire or cables quickly and economically.

Specification

Part No

As-Formed Dimension

SBW-PET-003-BK

Φ3.0

23±3

3±1

4±1

2~4

200

SBW-PET-006-BK

Φ6.0

28±3

6±2

8±2

4~7

200

SBW-PET-008-BK

Φ8.0

45±3

8±2

10±2

6~10

100

SBW-PET-010-BK

Φ10.0

53±3

10±2

12±2

8~11

80

SBW-PET-013-BK

Φ13.0

60±5

13±2

15±2

12~15

50

SBW-PET-016-BK

Φ16.0

76±5

16±2

18±2

15~18

200

SBW-PET-019-BK

Φ19.0

89±5

19±2

21±2

18~22

100

SBW-PET-025-BK

Φ25.0

115±5

25±2

27±2

23~26

50

SBW-PET-029-BK

Φ29.0

127±5

29±2

31±2

28~30

50

SBW-PET-032-BK

Φ32.0

143±5

32±2

34±2

29~34

50

SBW-PET-038-BK

Φ38.0

160±10

38±2

40±2

35-40

25

SBW-PET-050-BK

Φ50.0

205±10

45±2

48±2

46~51

15

SBW-PET-076-BK

Φ76.0

340±10

50±4

52±4

50~79

15

Application

The split braided sleeving is employed to shield wire harnesses, cable assemblies, tubing, and hoses within industries like automotive, railway, and machinery, among others, where minimizing vibration noise is crucial.

English

English