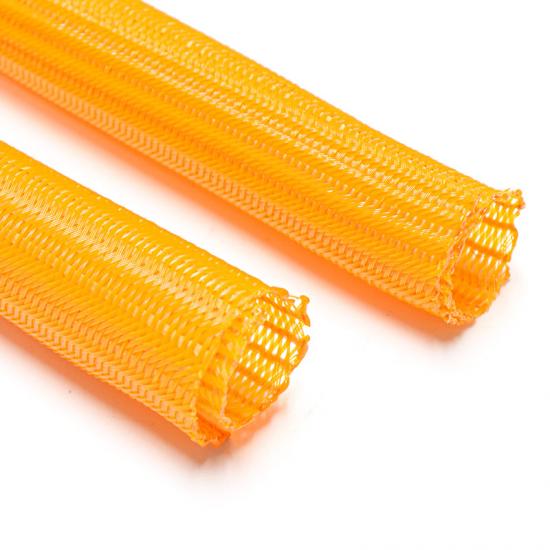

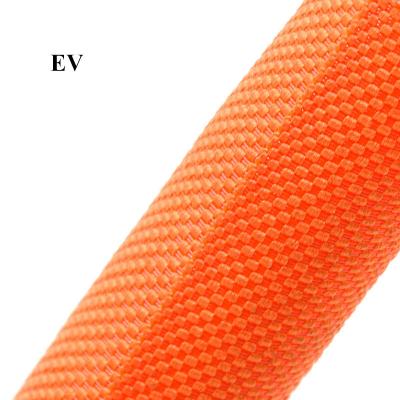

Automotive Orange-yellow Split Braided Wire Loom Cable Sleeve

Durability: Made from high-quality materials, these sleeves resist wear and tear, providing long-lasting protection for cables.

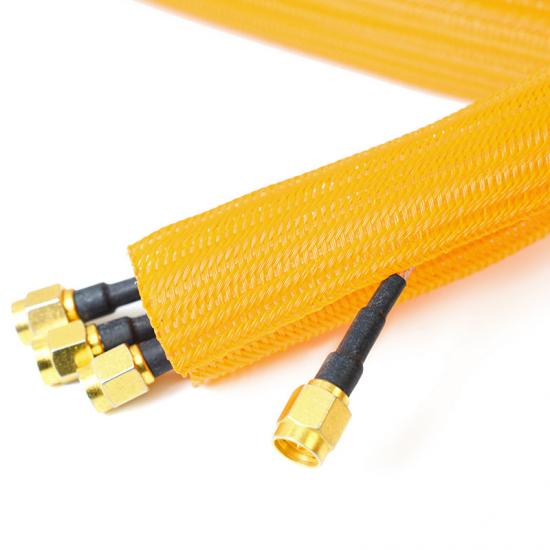

Flexibility: The split design allows for easy installation and removal, accommodating various cable sizes and configurations without the need for cutting or additional tools.

Heat Resistance: Many braided sleeves are designed to withstand high temperatures, making them suitable for environments with heat exposure.

Fraying Resistance: The braiding helps prevent fraying and damage to cables, maintaining their integrity over time.

Certifications

Physical Properties

Physical Properties

Details

Material

PET Monofilament + PET Multifilament

Working Temperature

-40°C ~ +150°C

Melt Point

240(±10)°C

Low Temperature Resistance

No crack and degradation after test at -40℃ for 4h

Short - term aging

No crack and degradation after test at 158℃ for 168h

Flammability

VW - 1, FMVSS302

Abrasion Resistance

Conform to grade 10(4000 cycles)refer to ISO6722

Liquid Resistance

No cracking or degradation refer to GMW14327

Ageing Resistance

Refer to ISO6722

Overlap

≧35%

UL File No

E533019

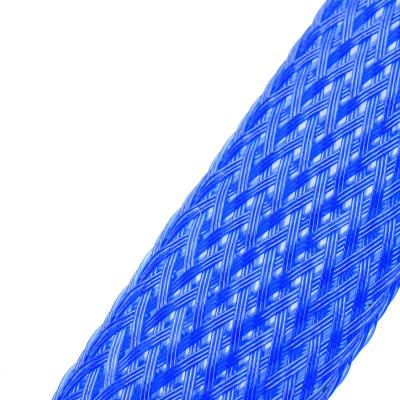

Standard Color

Orange

Certification

Rohs, Reach, UL, Halogen Free

Cutting Tool

Hot Knife

What's Special about Orange Split Braided Cable Sleeve?

1.Made of PET filament

2.Flammability: VW-1,FMVSS302

3.Extremely lightweight

4.Keeps it's flexibility under a wide range of temperatures

5.Easy, cost and labor effective installation

6.Resists gasoline, chemicals & cleaning Solvents

Specification

| Part No |

Nominal

Size

(mm)

|

Spread

Width

(mm)

|

As-Formed Dimension |

Bundle Dia

Range

(mm)

|

Packing

Length

(m/spool)

|

|

|

ID

(mm)

|

OD

(mm)

|

|||||

| SBW-PET-003 | Φ3.0 | 23±3 | 3±1 | 4±1 | 2~4 | 200 |

| SBW-PET-006 | Φ6.0 | 28±3 | 6±2 | 8±2 | 4~7 | 200 |

| SBW-PET-008 | Φ8.0 | 45±3 | 8±2 | 10±2 | 6~10 | 100 |

| SBW-PET-010 | Φ10.0 | 53±3 | 10±2 | 12±2 | 8~11 | 80 |

| SBW-PET-013 | Φ13.0 | 60±5 | 13±2 | 15±2 | 12~15 | 50 |

| SBW-PET-016 | Φ16.0 | 76±5 | 16±2 | 18±2 | 15~18 | 200 |

| SBW-PET-019 | Φ19.0 | 89±5 | 19±2 | 21±2 | 18~22 | 100 |

| SBW-PET-025 | Φ25.0 | 115±5 | 25±2 | 27±2 | 23~26 | 50 |

| SBW-PET-029 | Φ29.0 | 127±5 | 29±2 | 31±2 | 28~30 | 50 |

| SBW-PET-032 | Φ32.0 | 143±5 | 32±2 | 34±2 | 29~34 | 50 |

| SBW-PET-038 | Φ38.0 | 160±10 | 38±2 | 40±2 | 35-40 | 25 |

| SBW-PET-050 | Φ50.0 | 205±10 | 45±2 | 48±2 | 46~51 | 15 |

| SBW-PET-076 | Φ76.0 | 340±10 | 50±4 | 52±4 | 50~79 | 15 |

Application

1.Home and Office Electronics: Used to organize and protect cables for computers, televisions, and audio equipment.

2.Automotive Wiring: Commonly applied in vehicle wiring harnesses to protect against abrasion and heat.

3.Industrial Equipment: Employed in factories and machinery to manage and shield wiring from harsh conditions.

4.Networking: Utilized in data centers and server rooms to keep Ethernet and other networking cables organized and safe.

5.Marine Applications: Ideal for boats and marine equipment where exposure to moisture and salt can cause cable deterioration.

English

English