If those cables fail, the whole robot could stop working. That's why protecting them matters more than most people realize.

What Happens If Robot Wiring Isn't Protected?

Wiring inside robots faces a tough life. Without proper protection, you risk:Wires rubbing against sharp edges and breaking.

These small issues can snowball into expensive repairs or total shutdowns — especially in environments where uptime is critical.

Our BRS-PA66 Series Nylon Expandable Braided Sleeving offers a simple, cost-effective solution. It wraps around cables like flexible armor, shielding them from external threats and keeping everything organized.

Key Benefits:

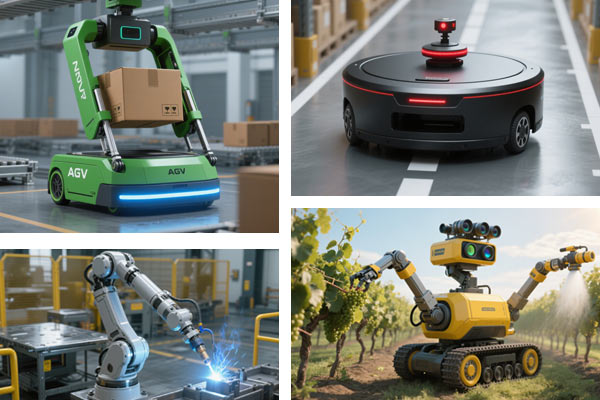

Whether it's an agricultural robot navigating vines, or a warehouse robot managing deliveries, sleeving protects the most critical systems:

| Robot Area | What It Protects |

| Battery Modules | Insulation from heat and sharp edges |

| Motor Connections | Vibration, friction, and motion damage |

| Sensor Wiring | Signal interference and mechanical wear |

| Control Circuits | Internal routing clarity and maintenance access |

| Tool Attachments | Twisting, pulling, and repeated movements |

Why It's a Small Detail That Makes a Big Impact

Using high-quality braided sleeving doesn’t just protect wires — it extends the robot's life, reduces maintenance costs, and boosts system reliability.

That's why leading robotics engineers make sleeving part of the design from day one — not as an afterthought.

Whether you're designing next-gen automation, retrofitting older systems, or improving reliability in harsh conditions, our BRS-PA66 braided sleeving can help.