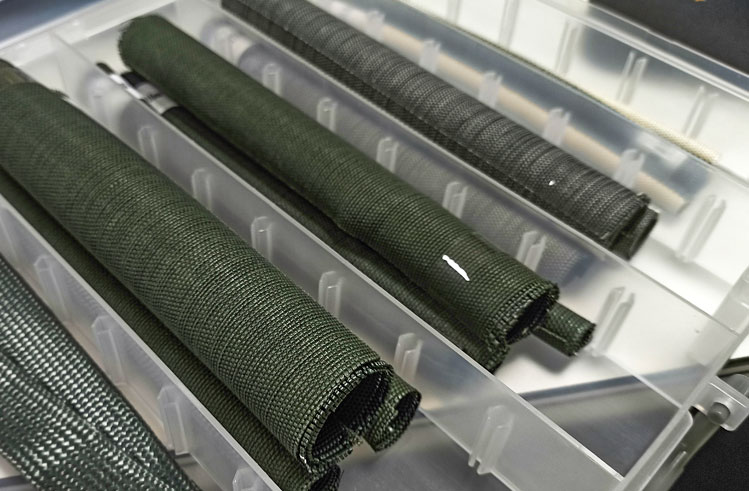

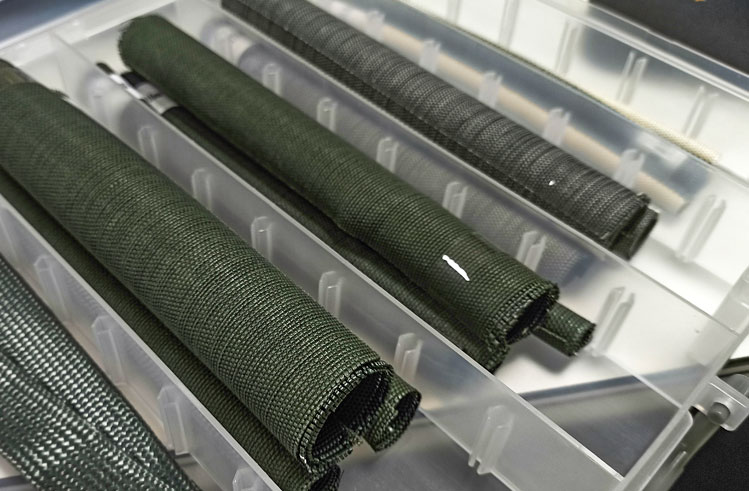

Amidst ongoing global supply chain realignments and surging demand for reliable industrial components, the need for high-performance, durable cable protection has never been greater. we engineer resilience into every millimeter of our braided sleeves — safeguarding critical wiring in automotive, aerospace, and robotics applications worldwide.

Why Precision Protection Matters Now:

-

Supply Chain Security: Consistent quality (ISO-backed standards) minimizes production downtime.

-

Electrification Demands: With EVs and renewables booming, heat-resistant materials like PEEK (0.1–0.5mm monofilament) and Aramid (200–8000D multifilament) ensure safety in high-temperature environments.

-

Localized Manufacturing: Our customizable sizing (05–70mm specs) supports regional OEMs adapting to "nearshoring" trends.

Engineered Excellence, Validated:

|

Key Feature

|

Performance Benchmark

|

Global Relevance

|

|

Heat Resistance

|

Withstands 44°C + 1127W/m² solar radiation

|

Critical for EVs & solar farms

|

|

Abrasion Defense

|

100+ cycles (steel needle test)

|

Ensures longevity in harsh environments

|

|

Tensile Strength

|

>0.02N/dTex pre-aging; <45% loss post-test

|

Meets EU/US safety mandates

|

Green by Design:

Our sleeves feature instant-visibility white markers (9mm centerline) against eco-green fabric — accelerating maintenance and reducing errors in automated factories.

Supply Chain Ready:

-

Flexible Packaging: 25m–150m coils optimized for logistics efficiency.

-

Rigorous QC: From raw material (≤0.10mm thickness tolerance) to bend/flame testing (1,000 cycles @ 10N).

For a World Demanding Reliability:

-

As industries seek alternatives to volatile supply sources, our sleeves deliver:

-

Traceable Compliance: Batch-specific certifications (ISO 9001 aligned)

-

Future-Proof Materials: PEEK/Aramid outperform PVC in sustainability & durability