Categories

Latest blog

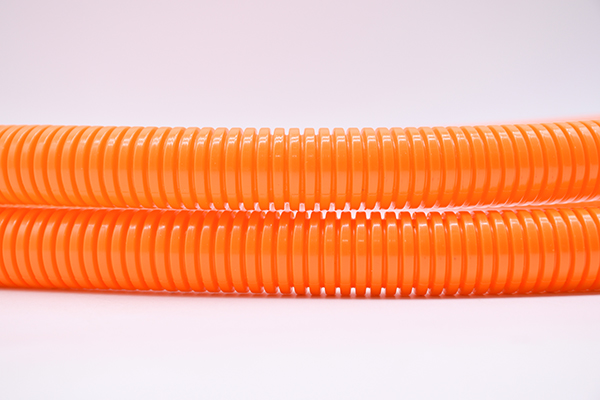

wire loom mainly have these three materials: PE (polyethylene), PP (polypropylene) and PA (nylon), which can achieve resistance High temperature 150℃ requirements, there are two materials PP and PA, the following mainly introduces the two kinds of high temperature corrugated pipe material difference And application selection.The material of PP wire loom is polypropylene, and the material of PA wire loom is nylon 6.

Polypropylene is colorless, odorless, non-toxic, and semi-toxic Transparent solid substance.

It is a thermoplastic synthetic resin with excellent properties. It is a colorless semi-transparent thermoplastic lightweight general purpose plastic.

with It has chemical resistance, heat resistance, electrical insulation, high strength mechanical properties and good high wear resistance.PA Chinese name polyamide,It is a general term for thermoplastic resins containing a repeated amide group - [NHCO] - on the molecular backbone.

It has high crystallinity and obvious melting point.surface High hardness, abrasion resistance, small friction coefficient, self-lubrication and noise reduction.Non-toxic, odorless, no mildew, self-extinguishing, weather resistance Good, but poor staining.

Nylon 6 is a material with the most superior comprehensive properties, including mechanical strength, stiffness, toughness, Mechanical shock absorption and wear resistance, coupled with good electrical insulation and chemical resistance.

PP wire loom and PA wire loom have halogen free, 150℃ high temperature resistance, UV resistance, friction resistance, acid, alkali, lubricating oil, Inorganic salts, good flexibility and other characteristics.

How to choose it in use?

First of all, in terms of temperature resistance, PA wire loom can withstand 175 ° C high temperature for a short time, which will be better than PP wire in terms of high temperature resistance .

In terms of physical properties, polypropylene is lighter than nylon 6, and the surface of the product is good and easy to color.

Therefore, want beautiful Color more choices, and higher weight requirements, can choose PP wire loom.In terms of mechanical properties, It is resistant to bending fatigue, in simple terms, PP wire loom will be more suitable for frequently moving mechanical wire harness protection.

In chemical stability PP wore loom are suitable for harness protection of chemical machinery with good anti-corrosion effect.In terms of electrical properties, PP wire loom almost do not absorb water, Therefore, the insulation performance is not affected by humidity, voltage resistance, arc resistance is good, but the electrostatic degree is high, and the contact with copper is easy to aging.

In terms of weather resistance, poly Propylene is more sensitive to ultraviolet light, so PA wire loom are more suitable for UV resistance than PP wire loom when used outdoors.

In terms of price,The cost of PP bellows is low, and price-sensitive customers will be preferred.

In short, PP bellows and PA wire loom have their own advantages, and the specific selection should be combined with the use of customers.

If you want to know more, such as the cable sleeve,heat shrink tube,hose protection sleeve. please contact us.